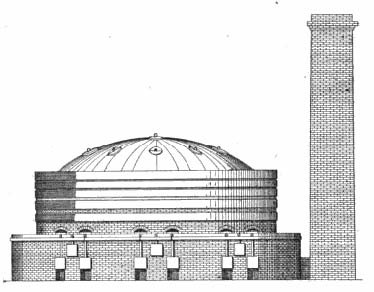

The accompanying cut illustrates the Grath combined radiating floor and direct down principle as applied to round kilns; the round kiln construction is preferred by some clayworkers, especially tile manufacturers, one reason being that it is cheaper to construct than the square kilns, its iron binding being less expensive than that of a square kiln. By applying this system to kilns, either round or square, good results are obtained, as this construction obviates many of the difficulties encountered in regular down-draft kilns. In the direct down-draft kiln the ware on top is often overburned to a certain extent, whereas the ware on the floor is rarely sufficiently burned. In the radiating floor construction, where the kiln is burned by having all the heat drawn from the furnaces under the radiating floof, throughout the entire process of burning the ware on the floor is burned harder than the ware in the center of the kiln, as the ware in the center is the greatest distance from the heat of the furnaces.

In the combined radiating floor and direct down-draft system the operation of the kiln is under entire control at all times; the heat can be directed under the radiating floor as long or as much as desired, by working dampers over the furnaces; the heat can also be applied to the ware on top direct, as long or as much as desired, and in this way the heat is evenly distributed, and a perfectly burned ware is the result. This kiln can be constructed as cheaply as others, and with a Grath gas and coking furnaces attached can be operated at a great reduction of expense by the use of soft coal, slack or dust for fuel. For further information, the Illinois Supply & Construction Co., Century Building, St. Louis, Mo., may be addressed.

Source:

Brick and Clay Record

Volume XII, Number 6, June 1900

Windsor & Kenfield Publishing Company, Chicago, IL

Page 257