When Mr. Habhegger discovered brick clay in the area of Wrenshall in 1883, it was the beginning of an industrial era for this tiny community. At first the whole area was covered by large white pines that had to be cleared away before the brick plant could be set up. If you visit Wrenshall today, you will find much of it covered with deep holes where the clay was removed. Some of them must have had hardpan bottoms as they have filled with water and are ponds. I’ve often wondered why no one attempted to plant them and then stock with fish as they are too deep for swimming. One local lad was swimming with friends, George (unable to decipher last name), and dove off the loading ramp. He came up under the ramp and was unable to find air, drowned under there. The other boys kept diving until they found him and brought him to the surface but it was too late to save his life. It was a sad day for Wrenshall when this accident occurred.

It took many buildings to start this operation. First a house large enough to accommodate his large family and also house and feed the men he would hire to work the plant. The blacksmith shop was necessary to keep the plant in repair and shoe the many horses needed. Then a large barn to house the horses and the harnesses, cows for milk and many heads of feeder cattle to use for food. I remember that he would have cattle shipped in by the carloads and driven to what was then known as Shiels place, which my father later inherited and sold to Orville Storey. There the cattle were turned loose in an 80-acre pasture and water was provided from a well where water was pumped into a large stock tank every day.

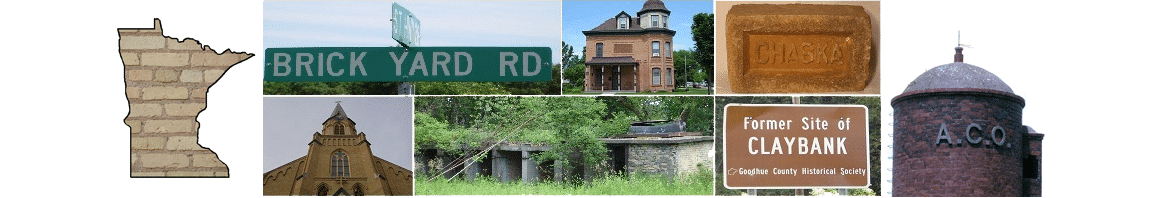

The plant itself required a large building for mixing the mud where a stationary engine was housed to haul the clay cars up to be emptied and the mud mixed. The bricks were formed and cut as the clay moved down to the chute to a conveyor where they were picked off by hand in 2’s and 3’s and placed on a special wheelbarrow and wheeled to the drying sheds, placed in such a way that air could circulate around them and they were left there for drying. Later they were moved to the big sheds called kilns where they were again spread so the heat could penetrate to harden them. The fire was kept burning day and night for at least 13 days then they were allowed to cool before being loaded onto rail cars and sent on their way to be used in buildings all over the USA.

Now to go back to the beginning. First the land was cleared. Then a loading ramp was built of planks with a cover for shade for the operator and to keep the engine dry. That was necessary to haul the clay car to the top of the banks as the pit got deeper and deeper. The clay car was placed under the ramp where a large opening had been left in the center to empty the clay from the wheelers. The wheelers were large shovel-shaped iron scoops that could be lowered into the clay and then lifted by the driver of the horses and a helper, locked into full position and pulled to the ramp. The horses soon learned to walk on one side of the opening and as the wheeler passed over the opening it was unlocked and tipped the clay into the car below. When the car was full, it was hauled to the top of the pit where “Old Tom” a sorrel with a blaze face would be hooked onto it and he hauled it to the plant where it was hoisted to the top above the mixer, emptied and returned to the pit for refill. It took many wheelers and horses to do this tiring work. The engines were fired by wood as was the drying kilns. It was an art to wheel the barrows loaded with brick and many times in the spring when the plant was opening up, Granddad would have to enlist my aunts, Anna and Emma, to show the “greenies” how to wheel them as they tipped over very easily until you learned how to balance them. The tipped bricks were a total loss as it cost more to salvage them then it to let them go for scrap. There were plank wheel paths so the barrows almost rolled themselves from the weight after they were started down the planks.

The drying sheds were long narrow wooden forms where the shed roof could be hooked above out of the way until the bricks were placed and then lowered to keep out the rain. There must have been almost an acre of these sheds as they covered much ground and were quite close together. The kiln shed was built quite close to the railroad tracks so the bricks could be wheeled from the kiln into the box cars. It was a real art to place the bricks in the kilns for burning and not everyone was capable of doing it quickly and correctly. Mike Murray was a masterhand at this job and did it for many years, really until the plant closed in early 1919 because of lack of help. I think all my aunts met their husbands from men that came to work in the plant. Some of them came from distant places. Uncle John Barth Wolf from Switzerland. He was also called Uncle Wolf by us younger ones. I think he was very well-liked by all. Mike Murray came from Litchfield, MN and Chris Bandle from Wisconsin and Ike Hogle from Kentucky. Grandfather owned much land that was covered with timber so the crew that was kept year-round was put to cutting wood to be used the next season on the plant.

One team was used to haul hot dinners out to the woods for the men. I can remember when I was 3 years old, watching my dad walk away from the house in the dark in the morning with his ax on his shoulder to go to work. Uncle Martin, my mother’s oldest brother, either roomed with us or came to go with him as they walked away together. My dad ran the engine in the pit and I can remember walking over there on warm days to take him a drink of ginger water that my mother had prepared and how grateful he was to see me come. I used to love to watch the horses walk on either side of the opening and never step in it, which I fully expected to happen sooner or later. I can remember my dad telling about when they would come in at night with the teams and sleighs loaded with wood and how cold they would be but they didn’t dare get off and walk as the timberwolves were close behind the rigs. But as long as the men stayed on the sleds they would never attack them. I think they carried rifles some of the time but never remember hearing him say they ever shot any.

Grandfather used to have white sand shipped in. It was a delight to us kids as we could put white frosting on our mud pies until Uncle John put the run on us as it was forbidden. I think all his daughters took a turn at cooking in the boarding house but the one I remember is Aunt Em. I ate my dinners there my first year of school and we always had green tea at noon. I always saved my tea until last so I could dunk some of Aunt’s good molasses cookies. I still like the cookies made from her recipe. Uncle John was the chore boy and did things to suit himself, much to the chagrin of everyone else. If he felt like milking the cows at three in the afternoon, he did. He also had a driving horse and had to see that all of the stock tanks were full in the pastures. He was to see that the water pails were full and wood in the kitchen woodbox. Also wood in the main room, which was a large room where the men spent their evenings before retiring. There were many captain’s chairs although they didn’t have such a fancy name at the time. But they were sturdy and comfortable. Grandfather also had his business desk in there where he kept track of the men and their days. At that time you worked not hours [Julie’s note: we believe that means they got paid based on productivity]. That came later when the unions came into being.

The day started at 6:30 AM and ended at 5:30 PM with one hour at noon. It was just plain hard work for everyone as breakfast was at 6:00 AM. Then the noon meal, some eating at the table and some sent to the woods in the winter for the men. Then a big supper, all the dishes to do and table to set for breakfast before you could call it a day. Then there was the washing from all the beds, towels and the family wash. There were no washers so everyone had a chance to use the washboard. Then the clothes were boiled, rinsed twice with the last rinse containing bluing to keep the whites white. In the wintertime, it was a real problem to dry all the washing. The ironing was done with sad irons, heated on a wood stove and in the summer it was plain miserable to iron in that heat from the stove and steam from the clothes as they were well-starched to make the dirt come out easier the next washing and had to be real damp so they would iron smooth. I don’t think Aunt Em ever put an unironed sheet on a bed her entire life.

The whole plant burned in 1894 during what became known as the Hinckley Fire. I have heard Uncle Louis tell of unhitching the horses and leaving a drag with a wooden frame in the middle of a plowed field and the heat was so intense, it burned the wood on the drag. If you have never been involved with an uncontrolled fire, you have missed an experience you will never forget. Michael and I watched a movie on tv not long ago that brought back memories. In the movie they waited for the fire to burn to the building before trying to stop it and we always started a fire a distance from our buildings and let it burn out to meet the oncoming blaze. If the smoke got too strong, you got down on your hands and knees and crawled and sometimes on your belly with your nose to the ground. An unplowed field was a hazard as a fire could just sweep along, a few furrows always helped control the blaze if you had time. You always rescue something in a fire. Aunt Louise saved an old lamp and a clock that didn’t run. I’ve always been quite proud of myself because when our house was struck by lightning and caught fire, I saved Beverly’s baby picture, a pieced quilt I had just finished and a beautiful dresser set George had given me the previous Christmas. Also a set of new books we had gotten that week on birds, animals, trees and flowers.

Source:

Evelyn LaVoie, Fred Habhegger’s granddaughter

Provided by Julie Lucas, great-great-great granddaughter of Fred Habhegger