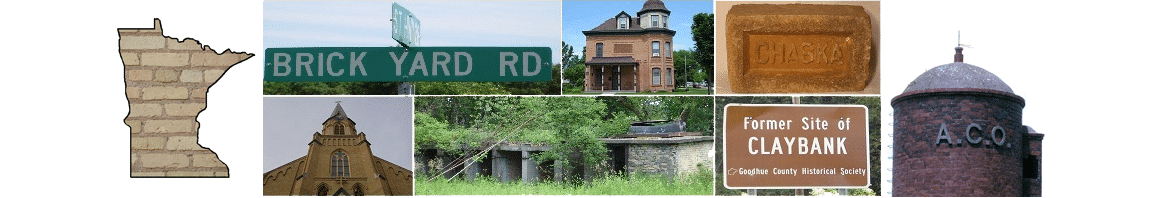

[Chaska] Page 140

The only place in Carver County where brick is being manufactured is at Chaska, on Minnesota River. Gray laminated river clays of the glacial River Warren, which was the outlet of Lake Agassiz, are used; and the gray drift and alluvium are not exploited in competition with this larger and better deposit.

The section at the clay it consists of 20 to 40 feet of partly stratified sand and gravel, underlain by 100 to 200 feet of dark-gray clay. These beds extend under the river valley for hundreds of acres. The laminated character of the clay shows that it was deposited when the river was greatly swollen by the melting of glacial ice. When the stream was rapid, sand was irregularly mixed with the clay and is now found as pockets, “wells,” and streaks. These, however, are so scattered that by mixing material from different parts of the bank a uniform quality of brick can be produced. The [unfired] clay slakes [quality by which a dry lump of clay tends to absorb water and fall to pieces when immersed] in one minute and shows a fairly high plasticity [capability of being molded], requiring 28 per cent of water for molding. Its tensile strength [maximum stress it can withstand before breaking] is somewhat variable, one briquet showing 200 pounds to the square inch and even the sandy layers yielding some strong briquets. Two pieces of clay when pressed together had almost no adhesion, showing, if the test is reliable, that defective auger structure may be developed. The average clay shows a shrinkage of 7.5 per cent on drying, but a mixture of some of the particularly sandy layers reduced this to 4.5 per cent, apparently without injuring the product. The clay burns buff up to the temperature of viscosity [change in form] and can be burned hard with very little shrinkage. Its absorption is over 20 per cent, even in well-burned brick as found on the market, but laboratory tests show that this may be reduced before reaching the melting point. The clay became hard at cone 02 (2,030° F.) and viscous at cone 4 (2,210° F.); and a half-and-half mixture with material from the particularly

Page 141

sandy layers gave very similar results. Four plants using this clay are in successful operation, employing over 300 men. All are under one management and use essentially the same method, having permanent oblong updraft kilns. Their aggregate capacity varies from 45,000 to 140,000 brick a day; in a recent year they produced 50,000,000 brick. Coal is the only fuel available. A large proportion of the product is solid cream-colored brick, some of which are made in the soft-mud machine. Three of the plants have facilities for making hollow ware, and three are provided with steam shovels for digging the clay. Of some products from Chaska tested by the Minneapolis building inspector two sewer brick showed a crushing strength of 4,250 pounds to the square inch; four miscellaneous brick in one set gave an average strength of 1,600 pounds; a set of 14 bricks, probably selected with some care (though this was not stated), had an average crushing strength of 2,635 pounds; two hollow bricks had a strength of 236 pounds; and one hollow tile with three horizontal openings had a strength of 158 pounds to the square inch.

The experimental engineering department at the University of Minnesota found that five soft-mud well-burned Chaska brick, tested dry, had an average crushing strength of 2,081 pounds to the square inch, a modulus of rupture of 658 pounds to the square inch, and an absorption of 22.2 per cent. Hollow building blocks had an average strength of 505 pounds to the square inch, a modulus of rupture of 600 pounds, and an absorption of 10 per cent. The wet brick had about the same strength as the dry.

Source:

Clays and Shales of Minnesota

By Frank F. Grout

With Contributions by E. K. Soper

United States Geological Survey, Bulletin 678

Washington, Government Printing Office, 1919