Page 194

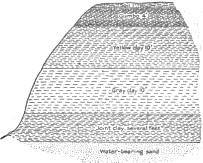

At Brickton, north of Princeton, two or more brick factories are at work upon a deposit of laminated clay, apparently of the common yellow-gray type, which extends across Mille Lacs County in a belt apparently controlled by the position of the glacial ice. Under the soil lies a superficial layer of clay, rarely over 4 feet thick, which has lost its laminated structure and which has apparently been so leached of lime that it burns red. Below this is 10 feet of yellow clay, underlain by 10 feet of gray clay. All these clays are usually worked together, mixed in the same proportion in which they are found. Below the gray clay is a considerable thickness of joint clay, which is reported as being greasy but which cracks too readily

Page 195

on drying to be satisfactorily used. Wells drilled through this joint clay find a water supply in gravel and sand just below it. (See fig. 28.) A few layers of the clays used contain ferruginous and calcareous concretions, but these do not cause much difficulty. As is usual in such deposits,

Sand occurs throughout in pockets or irregular streaks. The clay in some pits is more suitable for soft-mud than stiff-mud processes, but the main product is manufactured with stiff-mud machines. A smaller proportion is made light, for fire-proofing, by a central opening. Auger laminations cause considerable difficulty unless the clay is well mixed.

The clay slakes at once and develops only medium or low plasticity requiring 25 per cent of water. The shrinkage on drying is 7 per cent, and the tensile strength is over 150 pounds to the square inch, even when rapidly dried. Burning tests resulted as follows:

| Cone No. | Color. | Shrinkage | Absorption. |

| Per cent | Per cent | ||

| 05 | Salmon | 0 | 28 |

| 03 | Buff | 1 | 27 |

| 01 | …do | 2 | 24 |

| 2 | …do | 8 | 14 |

| 3 | …do | 10 | 8 |

They clay is hard after burning to cone 02 (2,030° F.) and reaches viscosity about cone 4 (2,210° F.).

The combined capacity of the plants operating at Brickton is about 15,000,000 brick in a season. The average brick produced were found by the experimental engineering department of the University of Minnesota to have a crushing strength of 2,000 pounds to the square inch.

The surface clay at Brickton, where weathered and leached, is reported as shrinking 8 per cent on drying, but it fuses about as suddenly as the main mass of clay. It has a good red color when burned.

Source:

Clays and Shales of Minnesota

Frank F. Grout with contributions by E. K. Soper

United States Geological Survey

Government Printing Office, Washington, D.C., 1919